Belleville Spring Washers

Freeway Corporation produces a variety of Belleville spring washers for industrial use. Our high-quality custom Belleville spring washers are designed to match our client’s specifications. All of the design and manufacturing of your Belleville spring washer is done in-house, allowing you to leverage our decades of experience all the way from design to production.

What Are Belleville Spring Washers

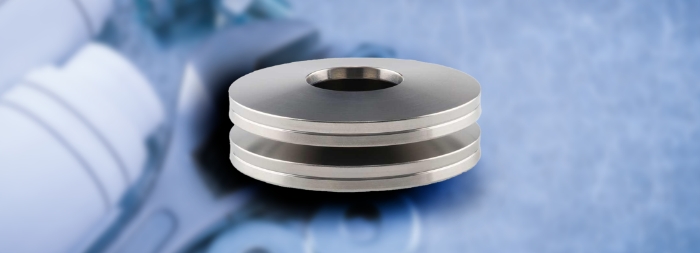

Belleville spring washers are known by a couple of different names depending on region and application. Sometimes referred to as coned disc springs or conical spring washers, a Belleville spring washer is a conically-shaped disc spring that flattens (deflects) under a specific load. The spring-like nature of standard Belleville spring washers applies a pre-load to the fastened hardware to prevent jostling and movement under stress. The amount of shock and vibration a washer can handle is your Belleville washer spring rate.

Standard Belleville washers are used in multiple industries and applications. However, there is some commonality in how they are used. Steel Belleville spring lock washers are used to absorb shock and counter vibration by applying a spring force on your hardware. Industries that use Belleville spring lock washers include:

- Automotive

- Aerospace

- Machining

- Pump Manufacturing

- Metalworking

Custom Belleville Spring Washers

Freeway Corporation develops custom Belleville spring washers in a variety of sizes and materials. We can produce heavy washers for use inside large industrial and agricultural equipment such as combines, tractors, bulldozers, loaders and conveyors. Our heavy-duty steel Belleville spring lock washers are made with HSLA steel, aluminum, brass or stainless steel and sized to meet your requirements.

Belleville Spring Washer Frequently Asked Questions

Learn more about our business practices and what Freeway Corporation can do for you with some answers to frequently asked questions regarding our Belleville spring washers.

What’s the Difference Between a Belleville Washer vs. a Spring Washer?

In reality, Belleville spring washers are a subcategory of spring washer. The conical shape of a Belleville spring washer is how it applies spring force on a bolted fastener. Other spring washers, such as curved washers and three-wave washers, use different shapes and forms to achieve similar effects.

What About Belleville Washers vs. Tooth Lock Washers?

Tooth-lock washers are also used to prevent movement and vibration of the bolted fastener but do so by providing additional points of fastening. Tooth lock washers are used especially in applications with softer metals and other materials where a consistent spring force is not desired.

How Do You Calculate the Potential Energy of Belleville Spring Washers

Belleville spring washers are unique in that they can be stacked in series or in parallel which provides additional spring force under load. This is known as the Belleville washer’s spring rate. The force-deflection relationship is nonlinear and depends on a multitude of variables including material thickness, washer width and free height available. Depending on how many Belleville spring lock washers you use determines the amount of potential energy you can achieve.

From standard Belleville spring washers to custom steel Belleville spring lock washers, Freeway Corporation is a worldwide leader in mechanical hardware production. With an in-house tool and die department, we produce high-quality Belleville spring lock washers that are engineered for today’s demanding manufacturing and industrial environments. In addition to design and production, Freeway Corporation can perform secondary operations such as plating, tapping, heat-treating and more. Contact us to learn more about Belleville spring washers and see what Freeway Corporation can do for you.