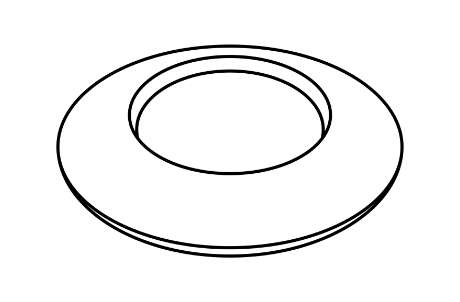

Conical Washers

Conical spring washers are used in many different industries. At Freeway Corporation, we produce high-quality conical spring washers designed to meet our client’s exact specifications for size, thickness and materials. Our design and manufacturing expertise can be leveraged to create your very own custom conical washers.

A conical washer, also referred to as a conical spring washer or Belleville washer, is used to absorb vibration and maintain preload in bolted joints. Conical washers provide a spring force that prevents bolts from loosening due to vibration or thermal expansion. Using multiple conical washers can allow for deflection of the bolt assembly which is useful in dynamic load environments.

Place the conical washer with the concave side (the smaller diameter) facing the surface of the material. The wider, convex side should face the fastener head or nut. Ensure the fastener (bolt, screw, or nut) is centered in the washer. Tighten the fastener to the recommended torque specifications. As you tighten, the conical washer flattens slightly, creating additional resistance against loosening due to vibration or dynamic loads. Proper installation helps conical washers prevent loosening and distribute stress across the assembly, improving the longevity and reliability of bolted joints.

There is no difference between a conical washer and a Belleville washer. The inventor Julien Belleville patented a spring design that was based on disc springs, and his name has since become synonymous with the conical spring washer. Other names for conical washers include coned-disc springs, cupped spring washers, conical spring washers and Belleville springs.

Custom Conical Washers

When you need heavy washers, there is no better place to turn than Freeway Corporation. Our heavy-duty conical washers can be made with all steel grades, aluminum, brass or stainless steel and sized to meet your specifications.

Utilizing our tool and die department, Freeway Corporation can produce high-quality conical spring washers on quick turnarounds to meet the demands of modern manufacturing. Produced under one roof, we provide some of the shortest lead times with prompt delivery of your conical washers. We can also complete post-processing and secondary operations in-house, including plating, tapping, heat-treating, deburring and more. Contact us today to learn more about our high-quality conical spring washer options and how Freeway Corporation can help you.