C WASHER STAMPING & MANUFACTURING

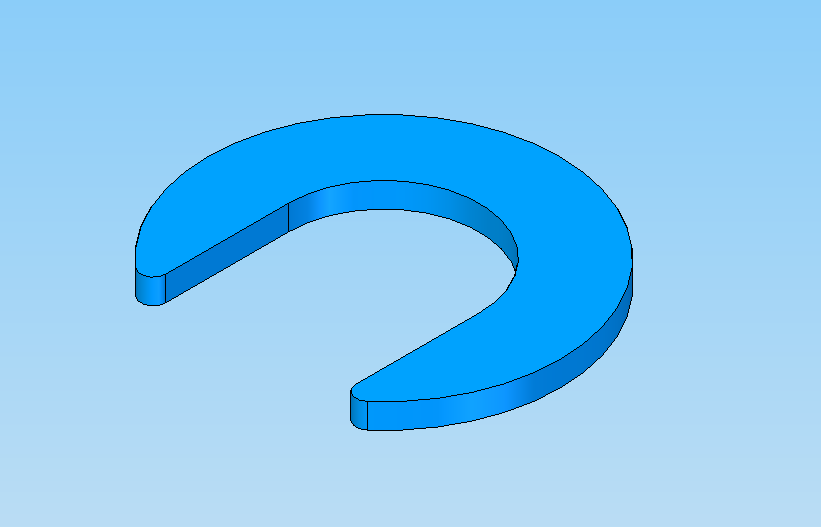

C washers, named for their unique “C” shape, are specialized fasteners designed with an open slot that allows them to be installed and removed quickly without disassembling other components. This feature makes C-washers ideal for applications that require frequent adjustments or where parts need to be changed rapidly, such as in machinery maintenance or assembly lines. Unlike standard round washers, which fully encircle a bolt or screw, the C-washer’s open shape allows it to slide into position sideways, saving time in scenarios with restricted access.

C Washers are also referred to as slotted washers. The primary function of a C-washer is to distribute loads and protect surfaces from damage caused by tightening bolts or screws. Additionally, they are often made from materials like steel, stainless steel, precious metals, or aluminum to withstand heavy loads and resist corrosion, making them suitable for both indoor and outdoor use across various industries.

SLOTTED WASHERS

Slotted washers, or C-washers, offer versatility in situations where limited access prevents the use of fully enclosed washers. They’re particularly useful in electrical assemblies, allowing quick disconnection and reconnection of grounding wires or electrical terminals. Their design also helps in aligning components during assembly, as they can hold parts temporarily in place without a full disassembly. Additionally, slotted washers are valued in automotive and aerospace applications, where they enable rapid part replacements and maintenance while minimizing downtime.

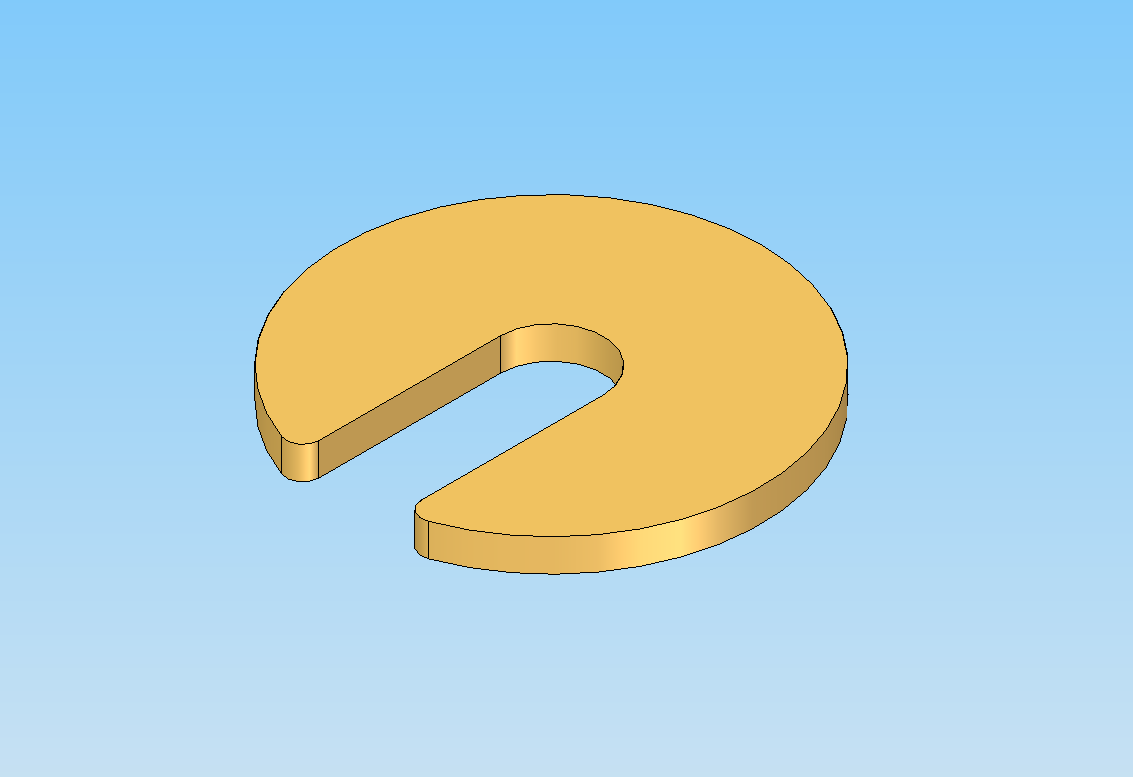

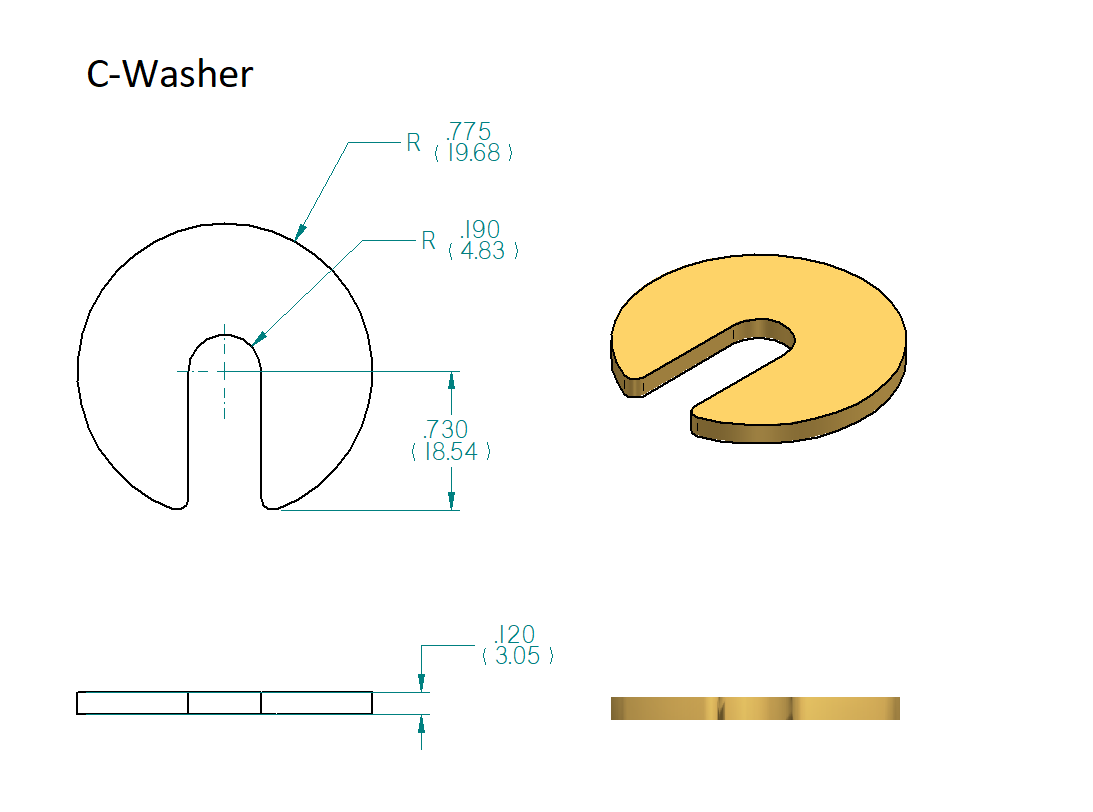

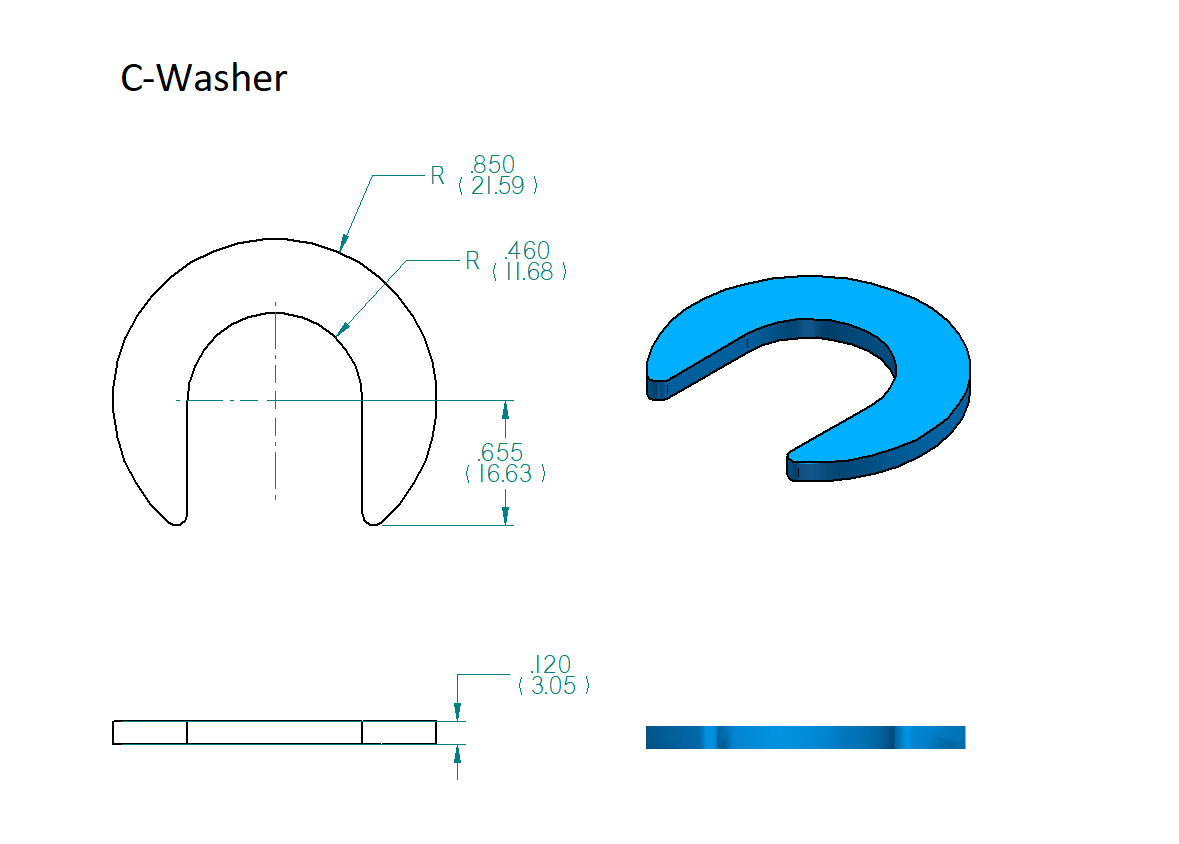

FLAT C WASHERS

Flat C-washers, with a smooth and open “C” shape, are used in applications where parts must align precisely while allowing for quick adjustments. These washers are often employed in fixtures and jig setups to ensure stable, flush contact with surfaces. In metalworking, flat C-washers help with clamping tasks, holding work pieces securely during machining without the need for full disassembly. Additionally, they are ideal for vibration-sensitive applications, as their design allows them to absorb small amounts of movement, protecting fasteners from loosening. Flat C-washers are also used as spacers, creating a controlled gap between components to prevent friction or wear.

STAINLESS STEEL C WASHERS

Stainless steel C-washers provide the strength and versatility of standard C-washers with the added benefits of corrosion resistance and durability, making them ideal for outdoor or harsh environments. Unlike regular steel, stainless steel resists rust, which makes these washers particularly suitable for marine, chemical, and high-moisture settings. Stainless steel C-washers maintain structural integrity over long periods, even when exposed to varying temperatures and chemicals, ensuring reliable performance in applications requiring longevity and minimal maintenance. They are frequently used in construction, electrical systems, and heavy-duty machinery where both quick adjustability and high resistance to environmental damage are necessary.

OTHER C WASHERS

C-washers can also be made from brass, plastic, and aluminum. Brass C-washers, for example, are used in electrical applications due to brass’s excellent conductivity and corrosion resistance. Plastic C-washers are ideal for lightweight and non-conductive needs, such as in electronics, while aluminum offers lightweight durability in aerospace applications.

C WASHERS FOR YOUR NEEDED APPLICATION

At Freeway Corporation, our team works closely with our customers to understand their projects and supply them with standard stamped washers and custom washers suited best for their applications. Our experience, skill and understanding of metal stamping allow us to manufacture high-quality stamped metal washers for a diverse set of industries. When you choose Freeway Corporation, you’re choosing a company you can trust with fair, competitive pricing.

C WASHER: FREQUENTLY ASKED QUESTIONS

WHAT IS THE PURPOSE OF A C WASHER?

A C-washer provides quick installation and removal capabilities by sliding onto bolts or screws without needing full disassembly. C-washers or slotted washers are great for applications requiring frequent adjustments or maintenance.

WHAT ARE C WASHERS USED FOR?

C-washers are used to simplify maintenance in machinery, electrical assemblies, and fixtures where parts require frequent adjustments. They are also valuable in applications with restricted access, allowing quick installation and alignment without fully removing fasteners.

WHY CHOOSE FREEWAY FOR C WASHER MANUFACTURING?

Choosing Freeway for C-washers ensures high-quality, reliable components designed with precision to meet customer specifications. With expertise in washer solutions, Freeway provides C-washers that offer lasting performance across various demanding applications.

If you have any questions about our precision washers, our brass washer stamping equipment, our custom washer creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-9700, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.