CHAMFER WASHER STAMPING & MANUFACTURING

A chamfered washer is a type of washer with an angled edge, designed to provide a better fit with a bolt heads. Chamfered washers are often used in applications where precise alignment is critical, such as in heavy machinery, automotive components, and structural assemblies. The chamfer edge of the washer also aids in creating a smooth transition between the fastener head and the material surface, which can prevent unnecessary wear and increase the lifespan of both the fastener and the components.

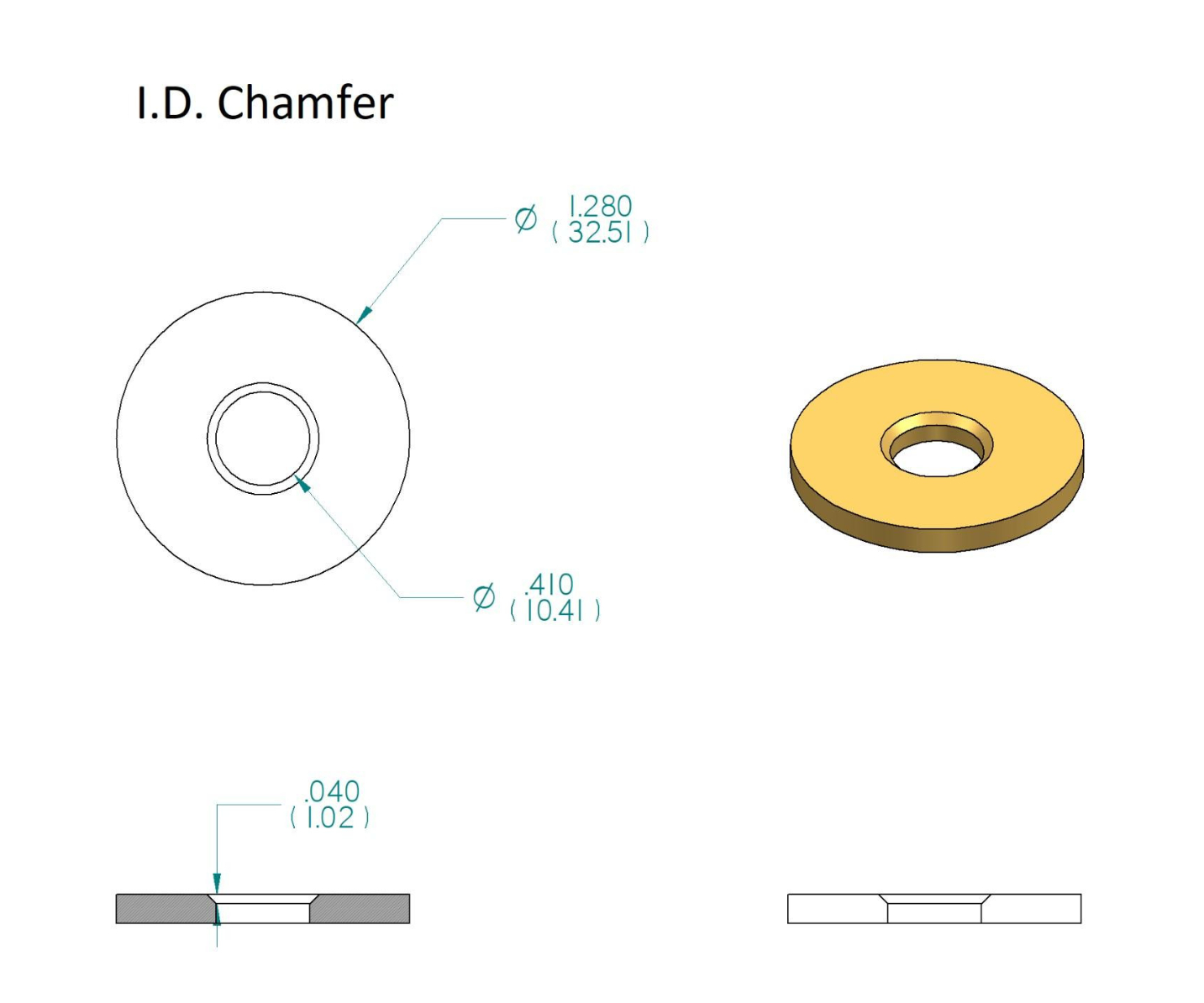

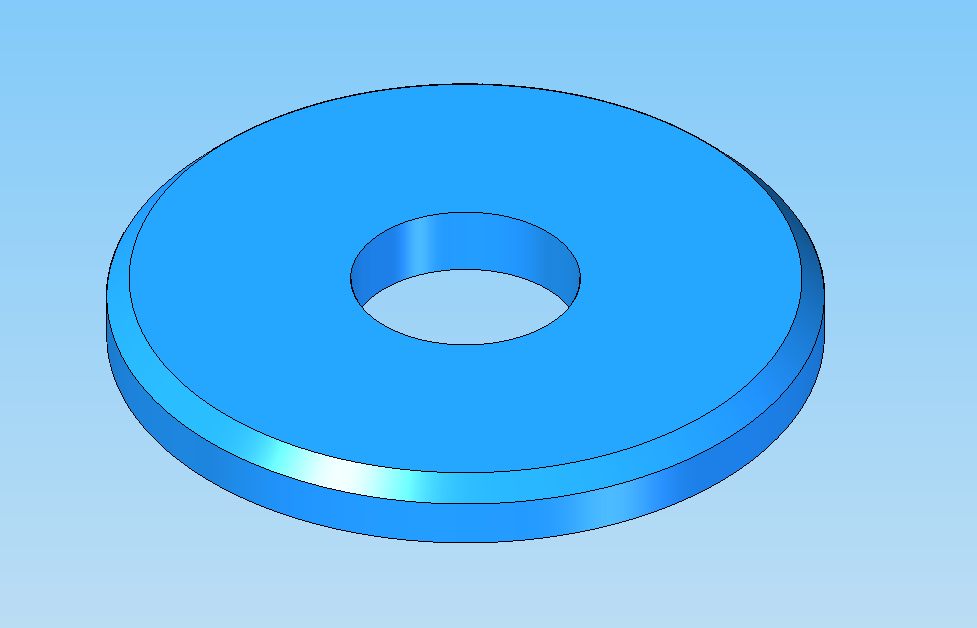

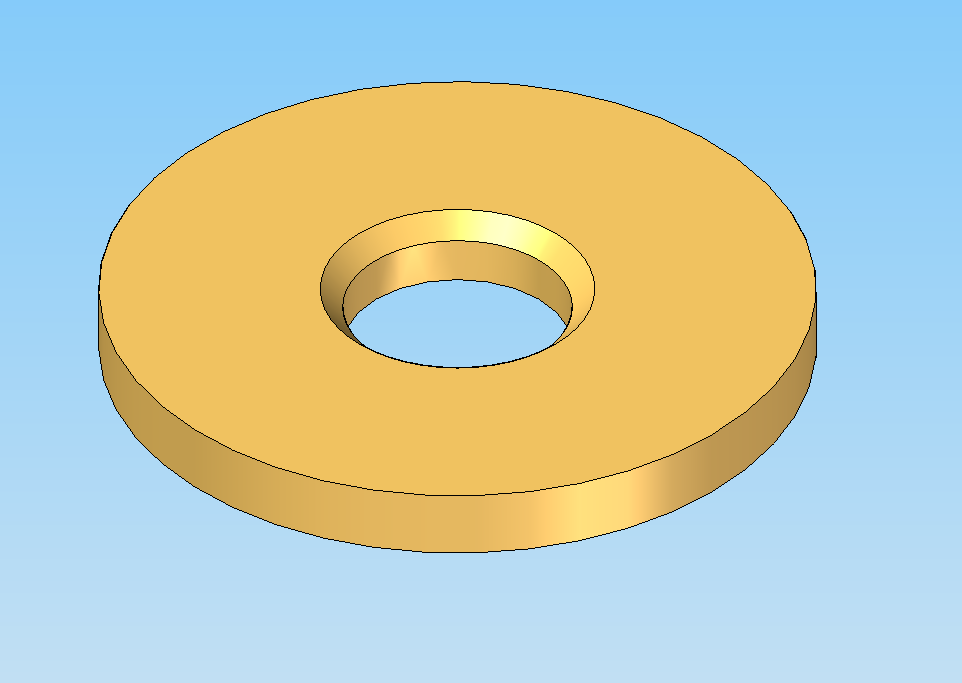

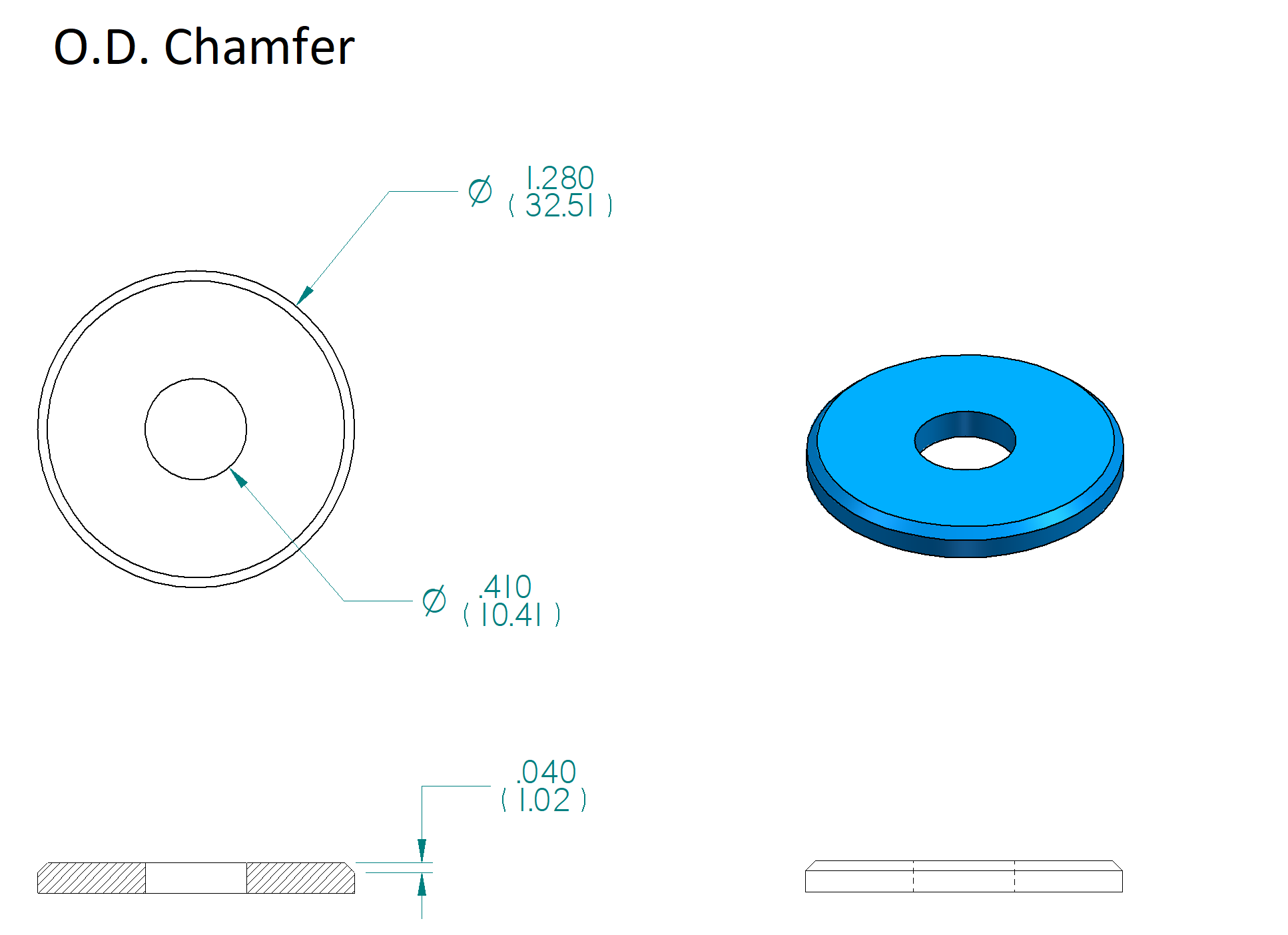

Our chamfered washers are available in various materials, including stainless steel, carbon steel, and other metals, making them suitable for different environments and applications. They are commonly used in conjunction with bolts and screws, where alignment and distribution of load are essential. Freeway has the capabilities to manufacture washers with a single chamfer (either on the OD or the ID), a double chamfered washer (same side OD and ID), or a double ID chamfer. Get in contact with Freeway sales today.

BENEFITS OF ID CHAMFERED WASHERS

The chamfer on the inside diameter (ID) of a washer offers several important benefits, particularly in applications where precise alignment, load distribution, and durability are critical. Here are the key advantages:

- Improved Fit and Alignment

- Ensures secure seating against rounded surfaces, reducing misalignment risks.

- Even Load Distribution

- Spreads force evenly, minimizing stress and material damage, especially on softer materials.

- Prevention of Fastener Head Damage

- Smooth transition reduces wear, prolonging washer and fastener life.

- Enhanced Torque Retention

- Maintains consistent torque, reducing loosening from vibration or thermal changes.

- Reduced Material Deformation

- Protects surfaces from damage under high stress or pressure.

Overall, an ID chamfer improves both the performance and longevity of fastener assemblies, particularly in demanding environments.

BENEFITS OF OD CHAMFERED WASHERS

A chamfer on the outside diameter (OD) of a washer offers several important benefits, especially in applications that require improved load distribution, smooth transitions, and enhanced durability. Here’s a breakdown of the key advantages:

- Reduces Edge Damage

- Prevents sharp edges from harming surrounding materials or surfaces.

- Improves Load Distribution

- Spreads stress evenly, reducing deformation risks under heavy loads.

- Prevents Surface Marring

- Smooth edges prevent friction or damage to adjacent components.

- Enhances Aesthetics

- Provides a polished, professional look for visible assemblies.

- Simplifies Installation

- Beveled edges make washers easier to position and handle.

- Increases Safety

- Eliminates sharp edges, reducing the risk of cuts during handling.

- Reduces Stress Risers

- Minimizes localized stress, lowering the risk of cracks or failures.

WHY CHOOSE FREEWAY CORPORATION CHAMFER WASHERS?

WHAT IS A CHAMFER WASHER?

A chamfer washer is a specialized type of washer with an angled edge, typically on the inner diameter (ID), outer diameter (OD), or both. The chamfer allows the washer to accommodate specific types of fasteners, such as bolts with a chamfered head or applications requiring the washer to sit flush against a sloped or angled surface.

WHAT IS THE PURPOSE OF A CHAMFERED WASHER?

The purpose of a chamfer washer is to help ensure a secure connection and distribute load evenly, especially in situations where regular washers would not fit properly. They are commonly used in high-stress applications such as automotive, construction, and industrial equipment.

WHAT ARE THE BENEFITS OF CHAMFEREING?

There are many benefits to chamfering a washer. Chamfering is used to improve fit, reduce wear and tear, and reduce risk of fastener loosening. Chamfering can also be used to orientate washers that are being bowl fed to where they are being assembled

If you have any questions about our precision washers, our brass washer stamping equipment, our custom washer creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-9700, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.