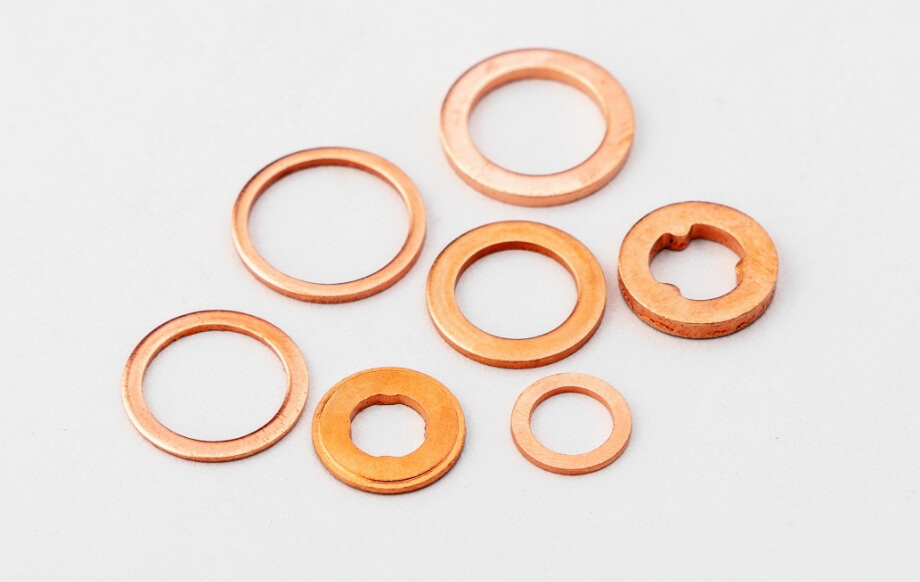

Copper Washer Stamping & Manufacturing

For decades, Freeway Corp. has specialized in producing high-quality/high-precision copper washers for an array of industries. We offer all copper washers tempers from ASTM B370. This includes O60 (soft annealed), H00 (cold-rolled annealed), H01 (quarter-hard), H02 (half-hard), H03 (three-quarter hard), and H04 (hard), and also offer a vast number of copper grades for our customer’s needs. When it comes to copper sealing washers, copper crush washers and copper flat washers, our advanced production techniques and commitment to quality ensure that every copper washer we produce exceeds our customer’s expectations. Whether you need custom sized copper washers or large-scale production, we deliver with unmatched efficiency and reliability. Choose our manufacturing expertise to meet all your copper washer needs.

Flat Copper Washers

Flat copper washers are used to distribute load and prevent leaks in various applications. Known for their excellent conductivity, corrosion resistance, and durability, these washers are ideal for electrical, plumbing, and mechanical uses, providing a reliable seal and stable connection.

Custom Copper Washers

Custom copper washers are specially designed to meet specific size, shape, and application requirements. They offer excellent conductivity, corrosion resistance, and sealing, making them ideal for tailored solutions in irrigation, marine, and automotive systems. Custom copper washers ensure precise fitting, reliable sealing, and optimal performance for unique and demanding applications.

Standard Copper Washers

Standard copper washers typically range in sizes from 1/8 inch to 2 inches in inner diameter, with outer diameters varying accordingly. Thicknesses usually range from 0.020 to 0.125 inches. These sizes are commonly used in various applications, providing a reliable fit and seal for a wide range of standard fasteners and connections.

Types of Copper Washers

- Copper Crush Washers: Standard round washers with a flat surface, used for load distribution and sealing.

- Cupped or Conical Copper Washers: Slightly curved washers that provide a spring-like action, helping to maintain tension in bolted assemblies.

- Shouldered Washers: Washers with an additional raised ring or shoulder, often used for precise alignment or spacing.

- Belleville Washers: Cone-shaped washers that act as springs, commonly used to maintain tension or absorb shock in assemblies.

- Sealing Washers: Washers with a soft, pliable material like rubber or silicone bonded to the copper, used to create a tight seal against fluids or gases.

- Custom Shaped Washers: Washers designed to meet specific application needs, including square, rectangular, or other unique shapes.

Copper Washers for Your Needed Application

At Freeway Corporation, our team works closely with our customers to understand their projects and supply them with standard stamped washers and custom washers suited best for their applications. Our experience, skill and understanding of metal stamping allow us to manufacture high-quality stamped metal washers for a diverse set of industries. When you choose Freeway Corporation, you’re choosing a company you can trust with fair, competitive pricing.

Why Choose Freeway Corporation Copper Washers?

Our copper washers have been used in countless projects to keep equipment working right, and designed for efficient use. Intricate and critical components like precision washers require exact technologies to meet your standards. At Freeway Corporation, our equipment and team expertise provide unparalleled speed to the market. We manufacture a wide variety of copper washers including spring washers, star washers, conical washers, and everything in between.

What Are Copper Washers Used For?

Copper washers are used in many different industries for different purposes. They are used to seal gaps between surfaces. The softness of copper, when torqued, can seal gaps and stop leak paths in industries such as automotive and agriculture. Another use of copper washers is for conductivity. Copper is a highly conductive material and can carry a strong current, making copper washers an important component in the electrical industry.

How to Soften Copper Washers

Annealing is the most common method of softening copper washers. The process involves heating the copper to a specific temperature and then allowing it to cool slowly. This removes internal stresses in the washer or copper in general and makes it easier to work with.

Why Use Copper Washers?

Copper washers offer excellent corrosion resistance, thermal and electrical conductivity, and mechanical properties that make them suitable for a wide range of applications.

If you have any questions about our precision washers, our brass washer stamping equipment, our custom washer creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-9700, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.