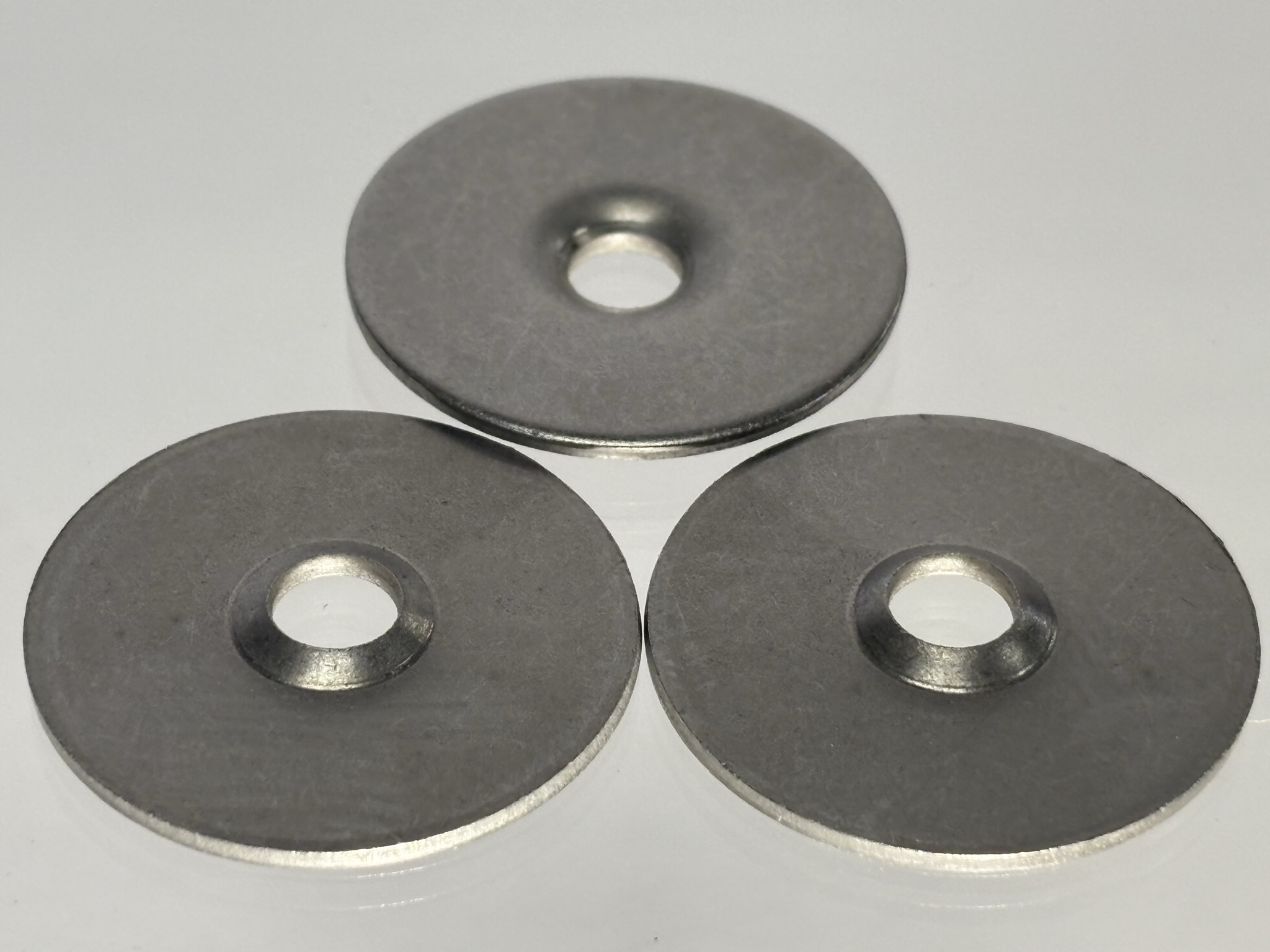

Countersunk Washers

At Freeway Corporation, we’ve built our reputation as a global leader in washer manufacturing by delivering precision, quality, and reliability. Our extensive product line includes countersunk washers, engineered for applications where a flush, seamless finish is essential.

Designed with a bowl-shaped profile, countersunk washers allow flat or oval head screws to sit level with the surface, enhancing both aesthetics and functionality. They not only provide a clean, professional appearance but also help prevent damage to softer materials by distributing the load more evenly. Whether for industrial, automotive, or custom applications, our countersunk washers deliver the durability and precision you need.

- Countersunk Design: Matches the angle of flat-head or oval-head screws.

- Enhanced Appearance: Creates a clean, professional finish by covering rough holes.

- Load Distribution: Reduces stress on the material, preventing cracking or pull-through.

- Material Options: Commonly made from stainless steel, brass, or zinc-plated steel for corrosion resistance.

- Applications: Used in cabinetry, furniture, marine, and automotive industries where a polished finish is desired.

COUNTERSUNK WASHERS MATERIALS

The material of a countersunk finishing washer impacts its durability, corrosion resistance, appearance, and suitability for different environments. Here’s a breakdown of the advantages of various materials:

1. Stainless Steel

- Corrosion Resistance: Excellent for outdoor, marine, and high-moisture environments.

- Strength: High tensile strength makes it suitable for heavy-duty applications.

- Aesthetic Appeal: Maintains a clean, polished look over time.

- Common Uses: Marine hardware, outdoor furniture, and construction.

2. Brass

- Corrosion Resistance: Good resistance to tarnishing and corrosion, especially in humid environments.

- Aesthetic Appeal: Gold-like appearance makes it ideal for decorative applications.

- Soft Metal: Won’t damage softer materials like wood or plastic.

- Common Uses: Furniture, decorative fixtures, and electrical applications.

3. Zinc-Plated Steel

- Cost-Effective: More affordable than stainless steel or brass.

- Moderate Corrosion Resistance: Suitable for indoor use, but can corrode in harsh environments.

- Strength: Stronger than brass but not as corrosion-resistant as stainless steel.

- Common Uses: General-purpose fastening in dry environments.

4. Aluminum

- Lightweight: Ideal for applications where weight reduction is important.

- Corrosion Resistance: Naturally resistant to rust but not as strong as stainless steel.

- Non-Magnetic: Suitable for applications where magnetism is a concern.

- Common Uses: Aerospace, automotive, and lightweight machinery.

COUNTERSUNK WASHERS APPLICATIONS

Countersunk washers are used in a variety of applications where a flush, secure fastening is needed. Some common uses include:

- Automotive – Used in vehicles to ensure smooth, aerodynamic surfaces and prevent fastener protrusion.

- Furniture & Cabinetry – Helps achieve a sleek, finished look while securing screws in wood, metal, or composite materials.

- Electronics & Appliances – Provides stable mounting for components while preventing damage to delicate materials.

- Marine & Outdoor Equipment – Stainless steel versions resist corrosion in boats, docks, and outdoor structures.

- Machinery & Manufacturing – Used in assembly processes to enhance structural integrity and prevent fastener loosening under vibration.

USING COUNTERSUNK WASHERS TO PREVENT MOVEMENT

Countersunk washers are also useful when a flush surface is required to prevent rotation or other movement. The countersunk washer has a flush surface that holds the part securely to prevent it from moving. When equipment or machinery is involved, the proper stability and alignment that countersunk washers provide can be especially helpful for safety and performance.

Using Stainless Steel Countersunk Washers to Prevent Movement

WHAT ARE THE ADVANTAGES OF USING COUNTERSUNK WASHERS?

Countersunk washers offer several advantages, particularly in applications requiring a flush and secure fastening. Other advantages of using countersunk washers are: load distribution, improved fastening, enhanced safety, and structural integrity.

WHY ARE COUNTERSUNK WASHERS USED IN WOOD REPAIR?

Repairing wood using a countersunk washer produces a smooth finish around the fastener’s assembly and helps you avoid splitting the surface or causing other damage.

WHEN SHOULD I CHOOSE A STAINLESS STEEL COUNTERSUNK WASHERS?

Stainless steel countersunk washers offer excellent durability, corrosion resistance, and strength, making them ideal for demanding applications. Their resistance to rust and oxidation ensures long-lasting performance, even in harsh environments

Whether you choose our stainless countersunk washers, heavy washers or any other type of washer from Freeway, you can feel confident knowing it’s manufactured to meet stringent industry standards. Using high-quality materials and a state-of-the-art manufacturing process, we ensure all of our washers are consistent in size and quality. Call our team of experts if you need custom washers in a non-standard thickness, size, material or finish. We’ll be happy to use our advanced machinery to turn your vision into the custom stamping components required for the task. Get your countersunk washers from Freeway today!