TOOTH WASHER STAMPING & MANUFACTURING

Tooth washers are specialized fasteners designed with serrated or pointed edges, which create a secure grip when compressed against a surface. These “teeth” help prevent loosening by digging into the surface or mating part, providing resistance to vibration and movement. Tooth washers come in two main varieties: internal-tooth and external-tooth. Internal-tooth washers have teeth around the inner edge, making them ideal for applications where the washer needs to sit flush with a surface and maintain a streamlined profile. External-tooth washers, on the other hand, have teeth around the outer edge, which provides a broader gripping area, useful for applications with larger bearing surfaces.

Commonly used in automotive, electronics, and mechanical assemblies, tooth washers add an extra layer of security, particularly in high-vibration environments. Made from various materials, including stainless steel and zinc-plated steel, they offer both durability and corrosion resistance for outdoor and high-stress applications.

TOOTH LOCK WASHER

Tooth lock washers enhance fastening stability by using their sharp, angled teeth to bite into both the fastener and the material surface, creating resistance against loosening. These washers are ideal for high-torque applications where traditional washers may fail, offering increased security in heavy machinery, construction, and industrial equipment.

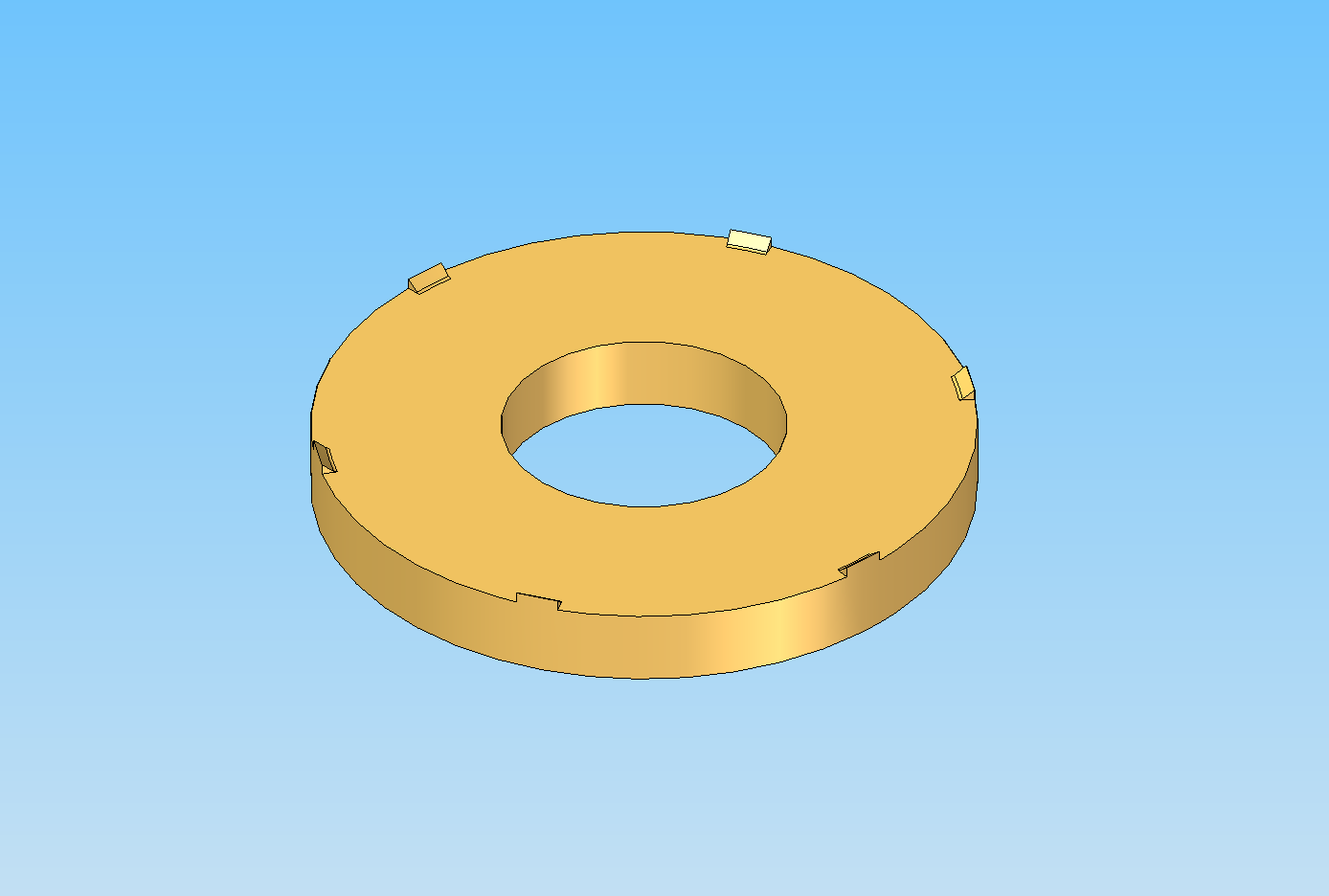

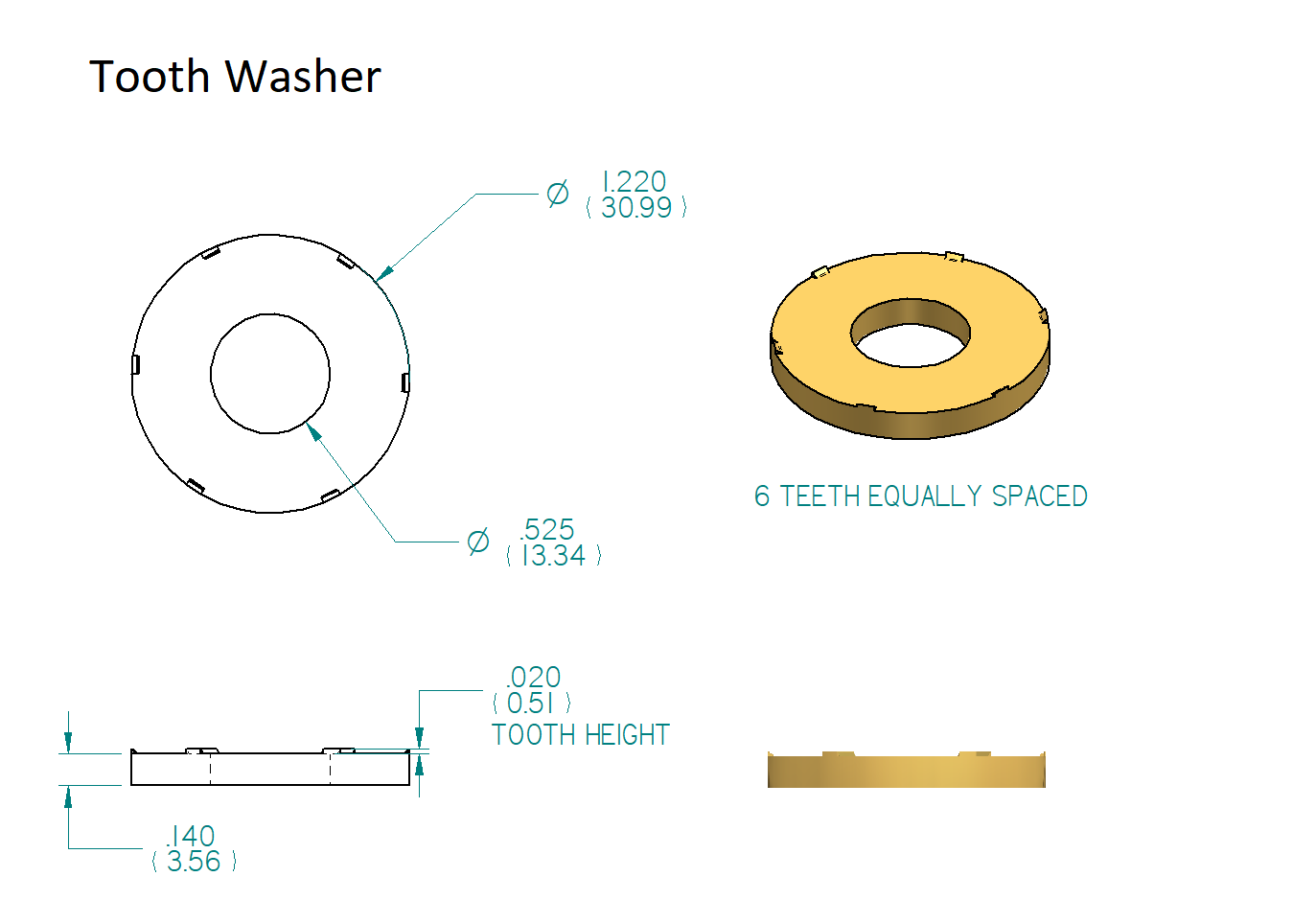

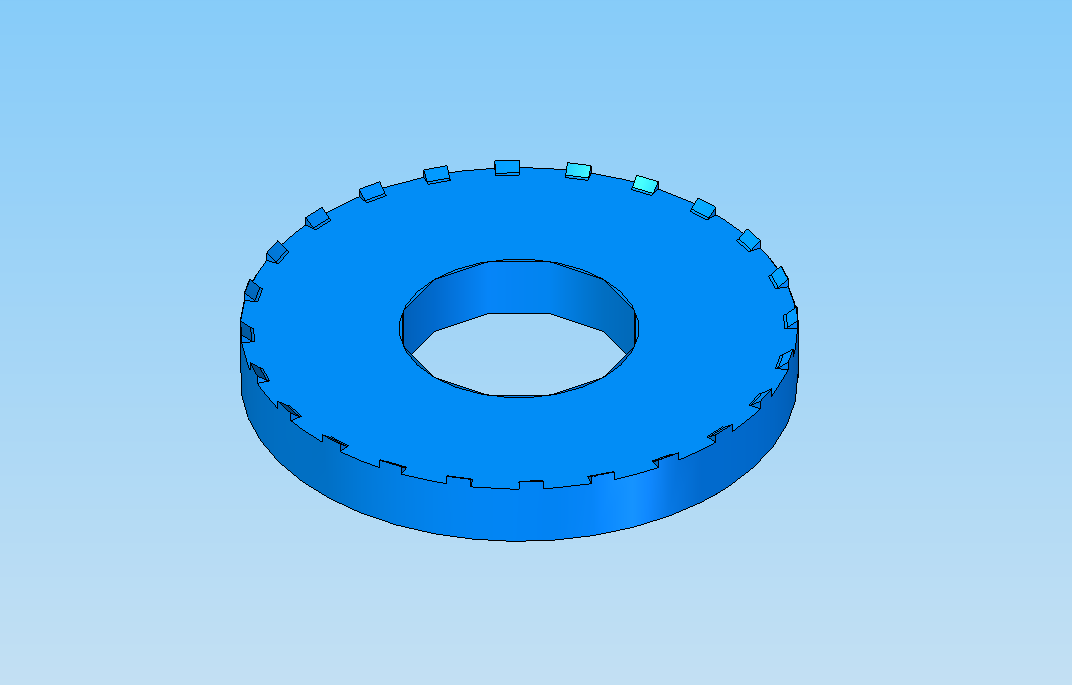

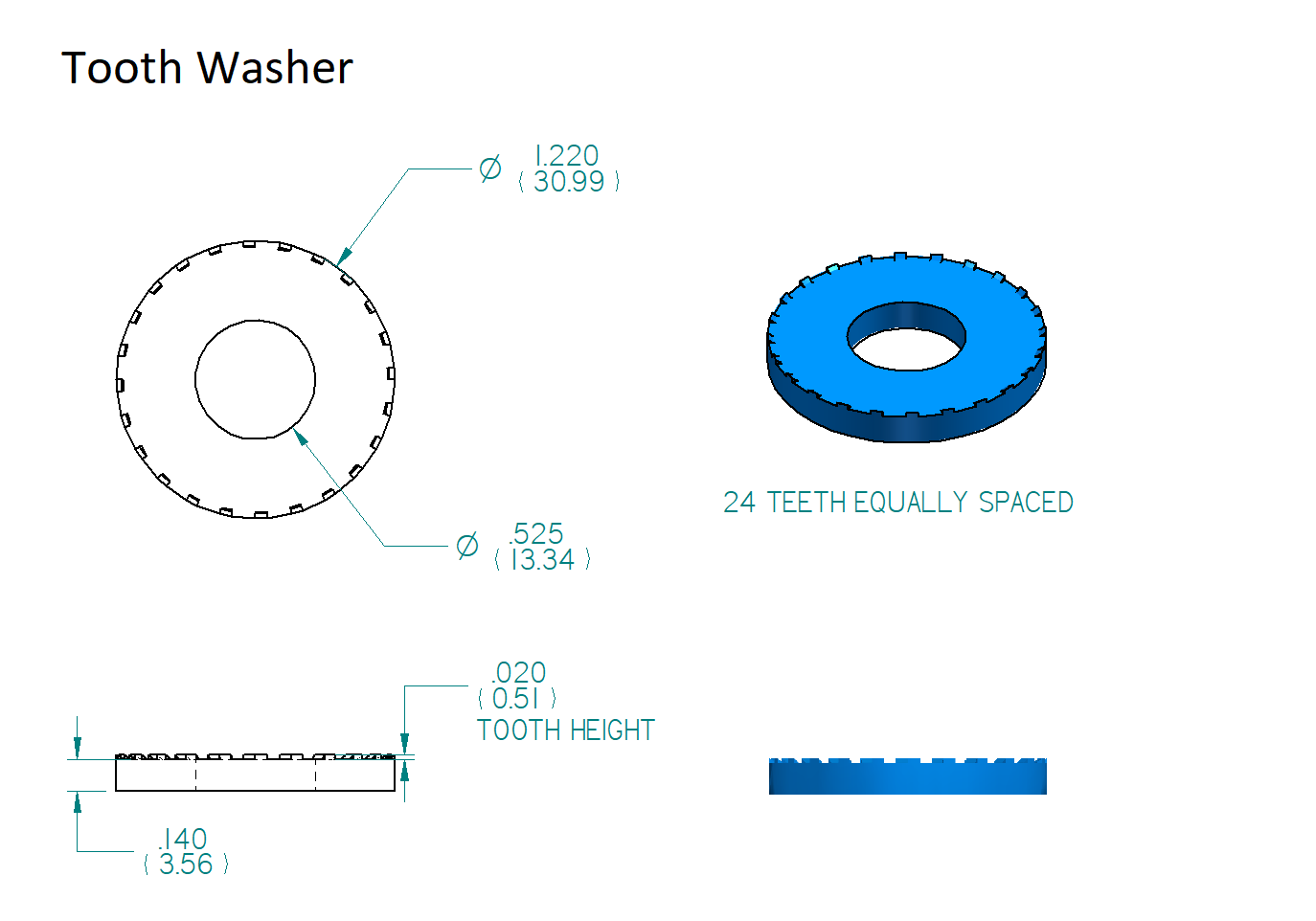

EXTERNAL TOOTH WASHER

External tooth washers have serrated teeth around the outer edge, providing a strong grip on the surface to prevent fasteners from loosening. They are ideal for applications where a larger surface area is needed for secure fastening, commonly used in electrical panels, machinery, and automotive assemblies where vibration resistance is crucial.

INTERNAL TOOTH WASHER

Internal tooth washers feature serrated teeth on the inner edge, which grip the fastener as it is tightened, preventing it from loosening. These washers are ideal for applications requiring a low-profile solution, such as in tight spaces or when a smooth outer surface is needed, commonly used in electronics and precision equipment.

OTHER TOOTH WASHERS

Tooth washers can be made from a variety of materials, including steel, stainless steel, brass, and zinc-plated steel. Stainless steel provides corrosion resistance for outdoor or harsh environments, while brass offers electrical conductivity. Zinc-plated steel is commonly used for its rust resistance, and steel offers more strength in general applications.

TOOTH WASHERS FOR YOUR NEEDED APPLICATION

At Freeway Corporation, our team works closely with our customers to understand their projects and supply them with standard stamped washers and custom washers suited best for their applications. Our experience, skill and understanding of metal stamping allow us to manufacture high-quality stamped metal washers for a diverse set of industries. When you choose Freeway Corporation, you’re choosing a company you can trust with fair, competitive pricing.

TOOTH WASHER: FREQUENTLY ASKED QUESTIONS

HOW TO USE TOOTH LOCK WASHER?

To use a tooth lock washer, place it between the fastener and the surface, ensuring the teeth are facing the material to grip and prevent loosening. Tighten the fastener as usual, allowing the washer’s teeth to bite into the surface, providing a secure, vibration-resistant hold.

HOW TO USE INTERNAL TOOTH LOCK WASHER?

To use an internal tooth lock washer, position it with the teeth facing the fastener, ensuring it fits snugly inside the bolt or screw head. Tighten the fastener, allowing the washer’s teeth to grip the fastener, preventing it from loosening due to vibration or movement.

WHAT IS A TOOTH WASHER USED FOR?

A tooth washer is used to prevent fasteners from loosening by providing resistance against vibrations and movement. Its serrated edges grip the surface or fastener, ensuring a secure and stable connection in applications where reliability and resistance to loosening are critical.

If you have any questions about our precision washers, our brass washer stamping equipment, our custom washer creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-9700, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.