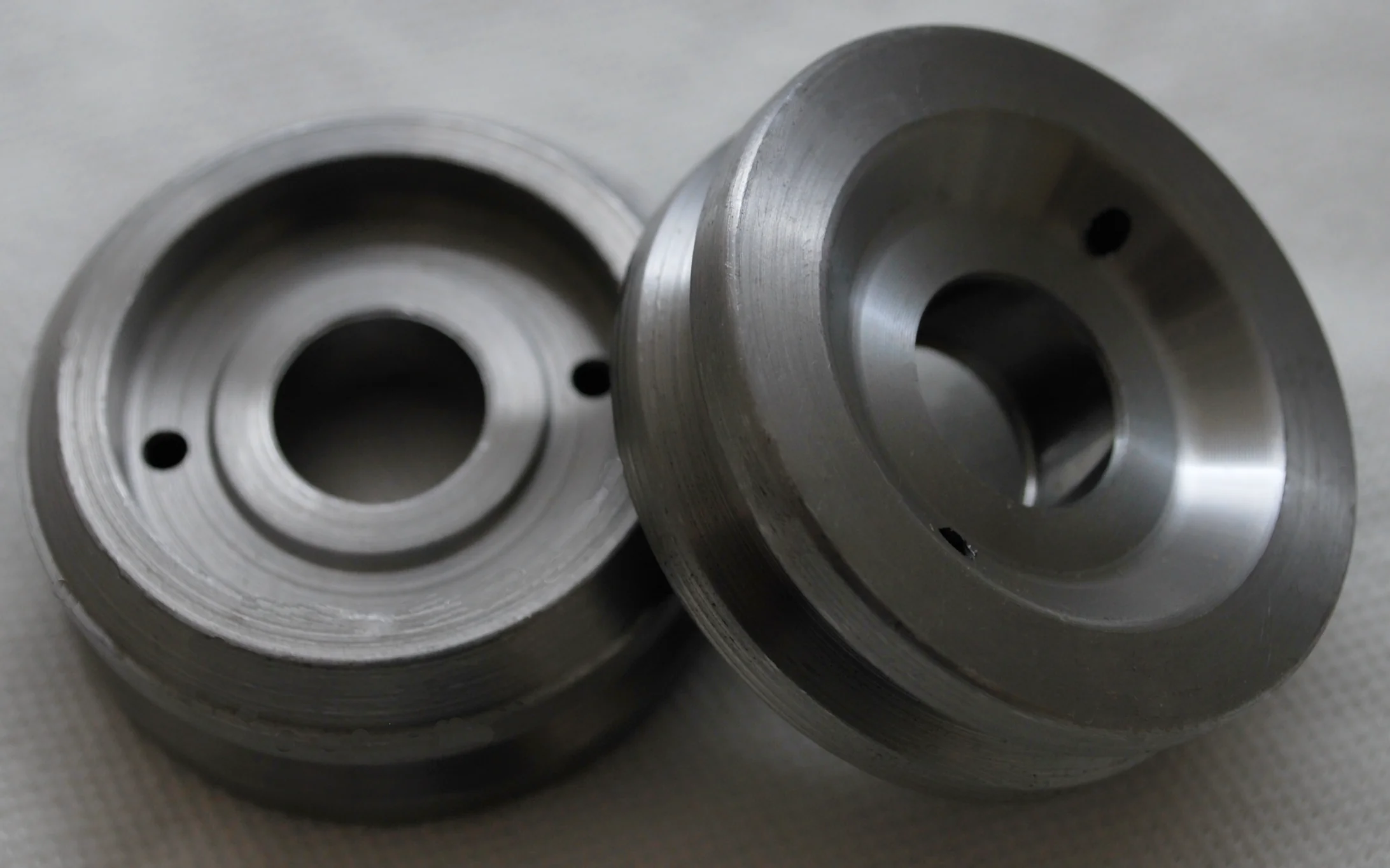

PRECISION TURNED COMPONENTS & CNC TURNED PARTS MANUFACTURING

In addition to our expertise in stamped components, we are a leading precision turned components manufacturers dedicated to producing high-quality precision turned parts. With state-of-the-art equipment and decades of machining experience, we provide precision turned components tailored to your specifications. Our machining department features over 30 multiple spindle automatic screw machines and CNC single-spindle turning centers, allowing us to deliver consistent and precise results for a variety of applications. Whether you need high-volume production or custom machining solutions, we have the capabilities to meet your needs.

Our current capabilities are below. However, we understand that some projects will dictate, depending on size and volume, new dedicated equipment. We have the resource available to procure the most efficient equipment solutions for your project.

Turned Products

- Automatic Screw Machines – Over 30 machines capable of machining up to 2 5/8” round and 2 5/16” hex materials.

- CNC Turning Centers – Multiple CNC lathes handling up to 2 7/8” bar stock and chucking up to 7” blanks for greater flexibility in part geometry.

Machined Components & Secondary Operations

We offer a full range of secondary machining operations to enhance component precision and functionality. Whether we are machining raw material or customer-supplied components, our secondary processes include:

- Broaching – OD, ID, and surface broaching for precise geometries

- Thread and Spline Rolling – High-strength rolled threads and splines

- Centerless Grinding – Achieving ultra-tight tolerances and smooth finishes

- Tapping – Accurate internal threading for assembly-ready parts

- Burnishing – Improved surface finish and durability

- Reaming – Precision hole sizing and finishing

- Milling – Complex part geometries with tight tolerances

- Drilling – High-accuracy hole creation for various applications

- Deburring – Clean, smooth edges for improved part performance

- Cleaning – Removal of contaminants for high-purity applications

- See our capabilities page for Additional operations

EXPERT MANUFACTURERS OF HIGH-QUALITY TURNED COMPONENTS IN THE USA

As an industry leader in precision turned product manufacturing, we take pride in providing American turned products that meet rigorous quality standards. Whether you require precision turned components for automotive, HVAC, or industrial applications, our team ensures each component is manufactured to required specifications.

- High Precision & Tight Tolerances – Ensuring reliable, repeatable accuracy in every component.

- Scalability – Capable of handling low- to high-volume production runs with efficiency.

- Comprehensive Solutions – From raw material machining to final finishing, we provide a full service solution.

- Industry Expertise – Decades of experience in machining and manufacturing turned components for various industries.

WHY CHOOSE FREEWAY FOR PRECISION TURNED MANUFACTURING?

Freeway excels in precision turned manufacturing by utilizing advanced CNC technology and multi-spindle screw machines for exceptional accuracy and efficiency. We specialize in machining a wide range of materials to meet diverse industry needs. With years of expertise and a focus on quality, we deliver high-performance components at any production scale.

WHAT ARE PRECISION TURNED PARTS?

Precision turned parts are high-accuracy components manufactured using CNC turning centers or multi-spindled turning centers, where a rotating work piece is shaped by a cutting tool. These parts are typically cylindrical and are used in industries such as automotive, hydraulic valves or fluid control, and agriculture due to their tight tolerances and consistent quality. Made from materials like carbon steel, stainless steel, brass, and copper, precision turned parts ensure reliability and performance in critical applications.

WHAT IS A MACHINED COMPONENT?

A machined component is a precisely manufactured part created by removing material from a raw work piece using machining processes like turning, milling, drilling, or grinding. These components are produced to exact specifications with tight tolerances. Machined components can have complex geometries, fine surface finishes, and precise dimensions, making them essential for applications that require high accuracy and reliability. Depending on the design, they may undergo secondary processes like threading, broaching, or deburring to enhance their functionality and performance.

WHAT INDUSTRIES WOULD USE TURNED COMPONENTS AND PRECISION MACHINED PARTS?

Turned components and precision machined parts are used in a variety of industries where high precision and performance are critical. Some of the key industries include: automotive, heavy truck, lawn & garden, agriculture, HVAC, exercise equipment, construction, mining, recreational vehicles, appliances, hydraulic valve, pneumatic control valve, bearings, marine, and energy.

Freeway Corporation is a worldwide leader in mechanical hardware production. With an in-house tool and die department, we produce high-quality washers that are engineered for today’s demanding manufacturing and industrial environments. In addition to design and production, Freeway Corporation can perform secondary operations such as plating, tapping, heat-treating and more. Contact us to learn more about what Freeway Corporation can do for you.